3D printed storage cases for compact, durable storage of metric hardware.

About the Project:

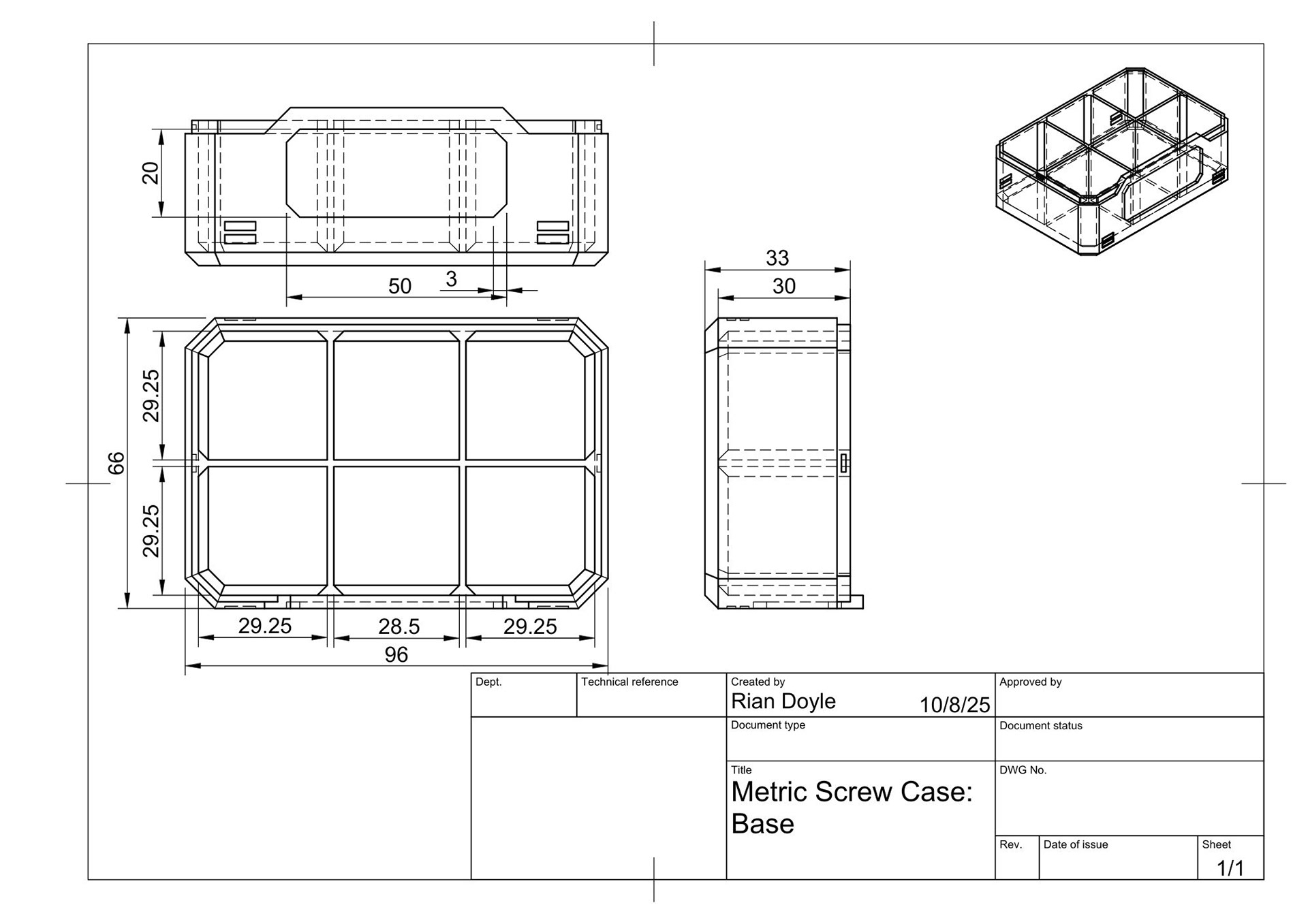

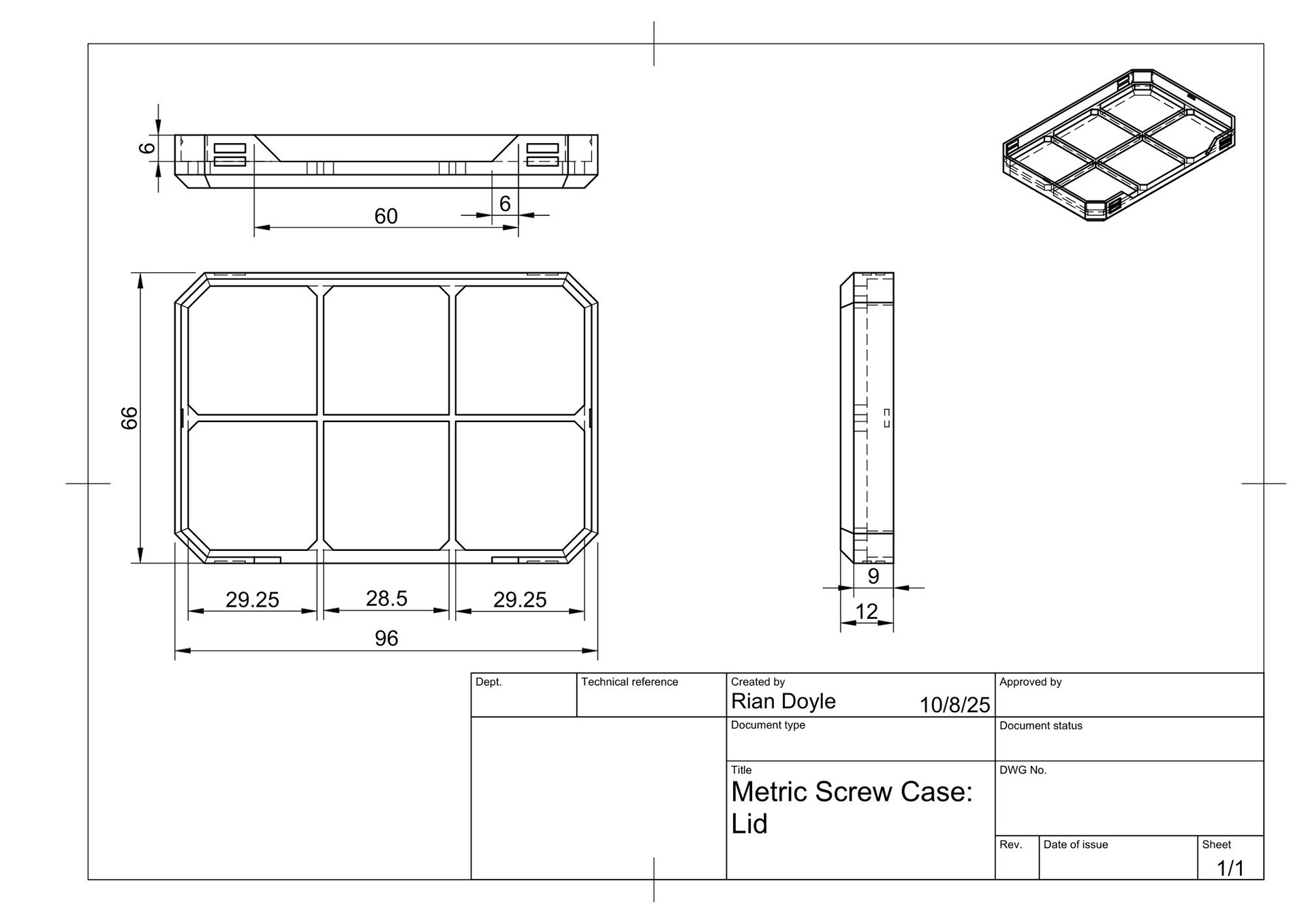

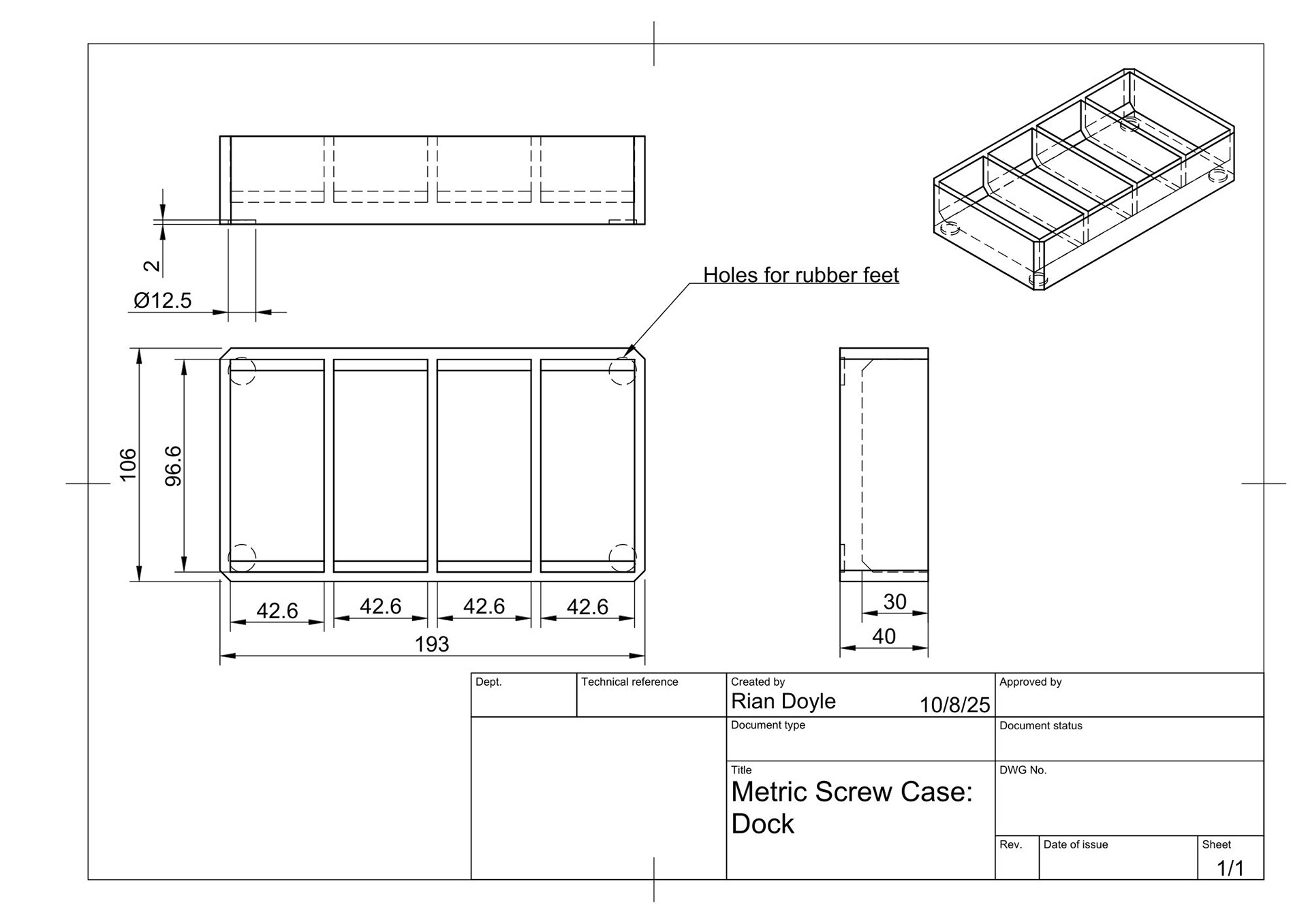

Designed in Fusion360, these cases include customizable labels, a dock that can hold four cases, and removable lids that double as trays. Each piece is designed to be printed on a standard FDM 3D printer with no supports. The individual cases are printed in three parts: the lid, the base, and the name tag. The lid has a tolerance of 0.1mm and two extrusions that click into the base to achieve a smooth, yet sturdy connection. On each corner of the front and back faces of the cases I inserted two inset notches. This design feature offers a grip to help open the top and visual interest. The white label is also printed separately, and can be slotted in the front using an interference fit. This means that different labels can be swapped out on the same case, but the labels will still stay in very firmly. The dock which holds four cases vertically, uses a clearance fit so that each case can be easily retrieved.

Design Process:

This project began as a sketch in my notebook. As with every project, I began with identifying the problem I was solving, and the specific criteria that I wanted to meet. I hand drew preliminary sketches, and jotted down general notes on the design. I then moved over to Fusion360, where I modeled each component. It took several iterations to achieve the desired tolerance between the lid and the base of the cases. After that I modeled the labels and printed out the final products on my Bambu Lab A1 3D printer. In this project, I learned how to dial in tolerances by using the cross section analysis on Fusion 360, and ultimately solved my problem by creating a secure and efficient way to store my metric hardware.

ALL Photos:

Isometric drawings: